Marine

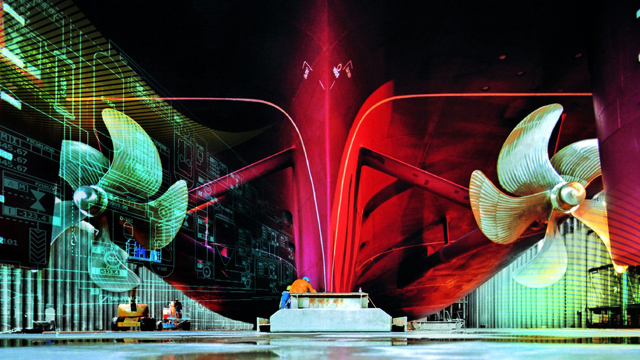

Digitalization for the Marine Industry

Siemens Digital Industries Software offers a comprehensive and integrated portfolio of software and services that covers all aspects of the ship lifecycle, from concept design through production to operations and optimized service lifecycle management. Our broad suite of state-of-the-art software solutions for the marine industry enables you to drive innovation and increase productivity to overcome today’s challenges while transforming your business into the digital enterprise of tomorrow.

Industry Segments

Commercial Shipbuilding

Increase vessel sustainability and shipyard productivity with Siemens Digital Industries Software holistic portfolio of solutions for commercial shipbuilding

Naval Shipbuilding

Improve future fleet availability, adaptability, reliability, cost, and performance with Siemens Digital Industries Software solutions for naval shipbuilding

Marine Suppliers

Meet today’s challenges with an integrated set of design, simulation, and manufacturing solutions for suppliers of marine equipment and systems

Yachts and Leisure

Offering state-of-the-art solutions for the design, production and sustainment of high-performance yachts and leisure craft

Owners & Operators

Optimize fuel consumption, maximize fleet performance and minimize vessels lifecycle costs with Siemens Digital Industries Software solutions for owners & operators

Ready to discuss your PLM needs? Contact our integration experts.

Featured Solutions

Integrated Ship Design & Engineering

Today’s marine market demands greener, smarter, and more high-tech vessels. To remain competitive, shipbuilders must deliver those vessels on time, on budget, and on quality. Our Integrated Ship Design and Engineering solution enables marine companies to remain in control of the design spiral. By bringing all their multidisciplinary design data, processes, and tools in one centralized environment, they can break down information and collaboration silos, boost innovation, and improve enterprise productivity.

Integrated Project Planning & Execution

As the demand for high value-added vessels increases, so does the need to identify and mitigate the risks associated with more complex design and manufacturing processes. This need is compounded by the current climate of unpredictability and increased competition in the shipbuilding market. To remain competitive, a shipyard must deliver bids that are both attractive and accurate. To this end, having a fully planned, resourced, and budgeted end-to-end project management solution has become critical.

Digital ship lifecycle management

To meet today’s regulations and market demands, ships need to be greener, safer, smarter, more cost-effective, more connected, and more adaptable than ever before. As new functionalities are added to what is already a highly complex product, more parties (e.g. suppliers, subcontractors, co-makers) need to be involved in the design, manufacturing, and maintenance processes. With ship service lives reaching up to 40 years for a commercial vessel and 50 years for a naval one, it becomes apparent that robust ship lifecycle management is not optional—it is critical.

Digital Ship Construction

Stricter environmental/safety regulations and increasingly customized functional requirements have been driving the demand for more complex vessels. This wave of complexity is hitting the shop floor just as increased competition and rising economic uncertainty are forcing shipyards to reduce their production costs and time-to-market. Shipyards must deliver on spec, on time, and on budget if they are to remain competitive. But when margins are low, how can shipbuilders keep reducing production costs without compromising quality?